Case Study:

Turning around Tomago Aluminium

Industry

Mining & Metals

Focus

Whole-of-Organisation Transformation

Impact

- 10% increase in output without additional CapEx

- $180M/year revenue uplift

- $3M reduction in injury-related costs

- 1M work hours without serious injury

- #1 ranked smelter in Australasia (efficiency)

Executive Summary

Want to hear it straight from the source?

You can listen to Matt tell the story in his own words — in a conversation with the Menzies Leadership Forum, he shares what it was like to lead this transformation from the top.

Listen here

The Challenge

Tomago Aluminium is one of the largest aluminium smelters in the Asia-Pacific region and the single largest electricity user in Australia. With over 1,100 employees and operating 24/7, the site plays a critical role in grid stability and the broader manufacturing supply chain.

When Matt Howell took over as CEO, the organisation was in crisis — both operationally and culturally. Six months after starting at Tomago, and having made some initial stabilising decisions, Matt called in Brent Sheridan, Executive Director of the Centre for Applied Transformation, to help architect and deliver the developmental processes for the senior teams that the turnaround required.

Key issues included:

- Safety Crisis: In 2013, there were nine recordable injuries in one year, including two serious disabilities. There were more than 30 people inactive on the books and workers’ compensation was $3M over budget.

- Low Trust Culture: Poorly thought through and bureaucratic systems reinforced surveillance, not accountability.

- Leadership Dysfunction: there had been a cumbersome leadership structure in place with sixteen senior leaders who lacked alignment or decisiveness and yet seemed to operate by consensus; nothing got decided quickly or effectively.

- Operational Instability: Emissions above limit, statutory inspections, and scheduled maintenance overdue, production behind plan and budget, poor product quality.

- Cultural Mistrust: Widespread justification, denial, blame, and resignation. Morale was low, behaviours were defensive, and staff expected plant closure — reflected in the nickname given to the new CEO, “Matt Finish”.

The Solution

“Ours was not a technical problem.

There was nothing fundamentally wrong with the asset.

It was the way we were relating to one another.”

Matt Howell, CEO of Tomago, 2013 – 2022

Matt led a transformation, with development processes designed and delivered by C4AT’s director Brent Sheridan, grounded in conscious leadership and cultural change. It was a development journey for his senior team and the next level of managers, focusing on how they interacted, solved problems, made decisions, and collaborated.

The transformation followed the Centre for Applied Transformation’s proprietary methodology, which integrates four dimensions of organisational capability – Mindset, Behaviour, Culture, and System – with the understanding of how they are all interdependent, ensuring coherence across organisational work and the business turnaround.

Unlike many conventional consulting approaches that address problems in isolation, this approach helped Tomago Aluminium Company's leaders understand and shift the deeper patterns driving their lack of performance. It created a shared framework for executive alignment, cultural renewal, and systemic change — ensuring the transformation was not just surface-level, but embedded, embodied, and sustainable.

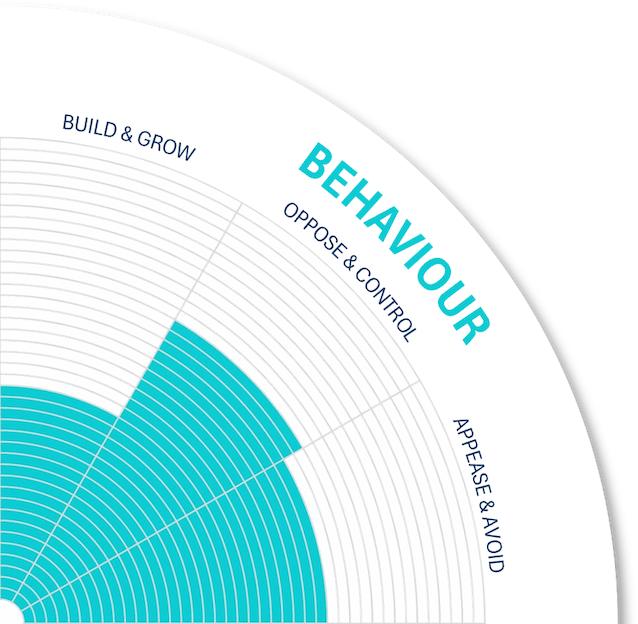

Behaviour

Transformation began by building a common behavioural language – improving coordination and consistency.

- Aggressive and passive behavioural norms shifted to more constructive ways of interacting.

- Leaders were held to a standard of constructive and “courageous conversations” and were supported to engage each other in peer-to-peer accountability.

- Leaders modelled new behaviours with each other and their people: from command-and-control to dialogue and listening.

- Safety was reframed around conversations, not mere compliance.

- Leaders publicly modelled vulnerability and adaptability (e.g. admitting when wrong).

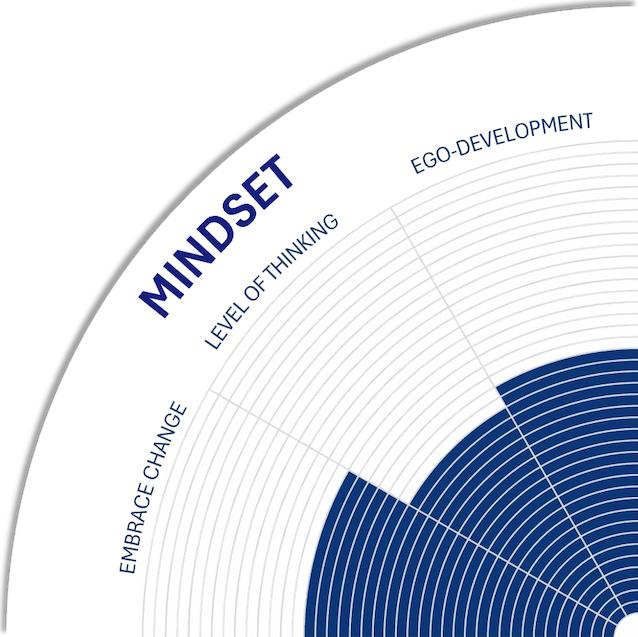

Mindset

Transformation continued by going deeper and supporting the leadership team to shift self-limiting beliefs that were blocks to their effectiveness.

- Self-awareness reset the psychological foundation for trustworthiness, accountability, and therefore high performance. The language shifted from “try” to “will” and became emblematic of the new mindset of taking personal responsibility.

- Executives led by example — “Demonstrate before you declare” became a leadership mantra, —signalling a new psychological contract across the organisation.

- Leader mindsets shifted from “It’s not safe here, so I will hide” to “I’m willing to be seen and heard, I make myself safe by telling the truth”

- Leadership mindsets shifted from ‘I need to show I am valuable’ to ‘I am curious to understand what you know or contribute’

- Shifted from top-down control to valuing and seeking frontline knowledge creating a learning organisation mindset.

Culture

Improving relationships became a competitive advantage: safety, quality, and productivity aligned.

- The leadership team stopped relying on reactive control logic (blame, compliance) and instead led with curiosity, clarity, and ownership.

- Management shifted from surveillance to trust (e.g. work-from-home policy: “We trust you”).

- Clarified and aligned purpose and intent: breaking production records while being both the safest and most efficient smelter, of their class, in the world

- Symbols of care were established (site clean-ups, green lawns, employee wellness programs).

- Desire for different perspectives being expressed was demonstrated creating psychological safety (e.g. union negotiation turnaround after public CEO challenge).

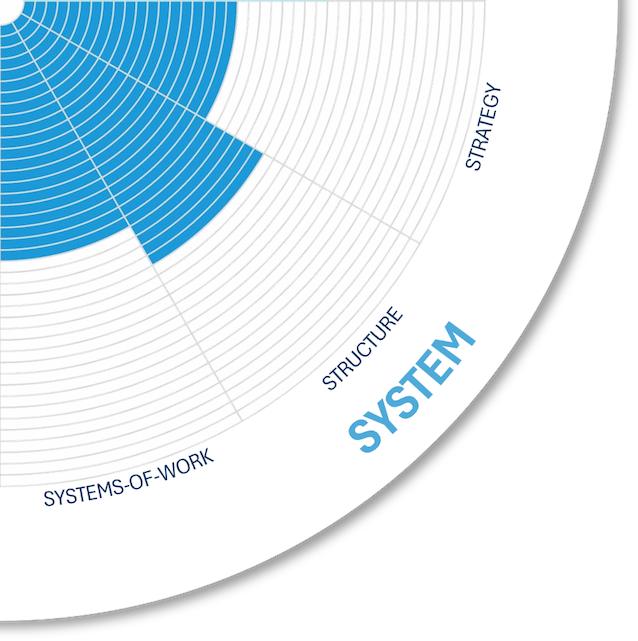

System

Simplified structures and systems as well as new meeting formats and cadences made new ways of working the default and structural.

- Systems were simplified (e.g. SAP approvals, absurd safety stop signs, synchronised rosters) to increase effectiveness, predictability and collaboration.

- Decision-making was spotlighted (e.g. “Whose decisions is this? And why?) and pushed down to the right level to enable responsiveness improving vertical flow of information and horizontal flow of work and value

- Located safety outcomes as the accountability of operations with safety elevated to number one priority

Results

Results of the development work supporting the turnaround and business transformation began to be seen quite quickly and continued to improve over the entire span of the work, from 2014 to 2022.

Operational Performance

- Tomago’s production soared exceeding the $100/tonne target — without CapEx, without layoffs, or deferred maintenance.

- The smelter’s output rose by 50,000 tonnes per year. This was achieved not by forcing throughput, but by running “more smoothly” – fewer disruptions, higher uptime, and a workforce empowered to optimise processes continually.

- By 2022 Tomago was the largest and most efficient aluminium smelter in Australasia

- Efficiency gains put Tomago at the top of global benchmarks.

Profitability and Cost Management

- Tomago experienced a major turnaround in profitability an increase of roughly 8–10% equating to ~$130M USD revenue uplift.

- Tomago saved millions in direct costs (lower injury-related expenses, repair costs, insurance premiums) and indirect costs (e.g. less lost production, better energy efficiency).

- They fostered a culture of financial diligence and innovation, targeting waste reduction and energy savings that cut costs while improving environmental and safety outcomes.

- In Matt’s words, by 2022 the business was “in a great position” financially, having achieved all its performance goals “and then some”.

“We seemed to lurch from one crisis to the next. Not only was that costing us a heap of money, people were tired of having to deal with this stuff every day. The turnaround came when our people were fired-up to do things differently.”

— Steve McIntyre, CFO of Tomago (Reflecting on early 2010s crises)

Safety

- The alignment of safety with operations created a reinforcing virtuous cycle.

- Tomago achieved world-class safety performance. By early 2019, the site reached one million work hours without a serious injury – a milestone that had never been hit before at this operation.

- The company won the region’s highest safety accolade, the “Gold Safety Helmet” for Workplace Health & Safety Business of the Year, recognising its innovative, employee-driven safety culture.

- Safety at Tomago became proactive rather than reactive; near-misses and hazards were being reported and fixed by teams before they caused harm, indicating a mature safety culture.

- Tomago was ultimately awarded a Self-insurance license on the basis of their massive injury and medical cost reductions.

“Tomago Aluminium’s ingrained health and safety principles made it a stand-out leader with an enviable record”

— Sarah-Jane Dunford, Hunter Safety Awards 2019

Employee Engagement and Culture

- Boardrooms to pot rooms aligned around a common purpose: “Care first, performance follows.”

- Psychological safety became normalised: frontline staff and superintendents challenging executive decisions respectfully.

- The change in morale and engagement at Tomago was striking. With leadership nurturing a “camaraderie” and even fun (celebrating successes, open communications), employees reported higher job satisfaction and commitment.

- Turnover rates fell which improved retention, as safety and respect improved working conditions. Workers became stakeholders in problem-solving, evidenced by robust participation in voluntary programs like the spring “Site Clean-up” days and idea submissions.

- Tomago’s cultural health not only recovered, it became known as a “benchmark operation… the smelter others look at and say: ‘Wow, how did they do that?”. This pride and external recognition further reinforced positive feedback loops internally.

- The intangible metrics – trust, satisfaction, pride – all trended upwards, creating a culture capable of sustaining high performance.

Conclusion & Takeaways

This transformation shows how real performance comes not from more rules, bigger systems, or massive material investment. Instead, it can come from better relationships, mindset shifts, value-creating social processes, and leader-led cultural rewiring.

Start with people, not metrics — performance is an outcome of belief, care, and clarity.

Psychological safety enables challenge, learning, and innovation at every level.

Leaders must create the environment and then get out of the way.